As an important high-temperature refractory material, refractory castables are widely used in the construction and maintenance of high-temperature equipment and refractory structures in industries such as metallurgy, glass, oil refining, and electric power.

When Rongsheng company castable manufacturers produce refractory castables, they usually recommend reasonable refractory castables based on the physical and chemical indicators of refractory castables provided by customers or based on the industrial kiln environment provided by customers and customize the processing to ensure high quality and meet the needs of industrial kilns. Furnace usage requirements.

Acid Resistant Castable

Main Features:Acid resistant castable has excellent acid corrosion resistance, high temperature resistance, thermal shock resistance and compressive strength, and can provide effective protection in high temperature and acidic medium environments.

Applications:It is widely used in high temperature fields such as chemical industry, metallurgy, electric power, etc., especially in the environment corroded by acid gas, molten metal and slag.

| Acid Resistant Castable | |

| Item | Index |

| Al2O3 % | ≥40 |

| Acid Resistance % | ≥98.5 |

| Bulk Density (110℃×24h) g/cm3 | ≥2.20 |

| Cold Crushing Strength (110℃×24h) Mpa | ≥30 |

| Cold Crushing Strength (1350℃×24h) Mpa | ≥45 |

Alkali Resistant Castable

Main Features:Alkali-resistant castables are engineering materials specially designed to resist corrosion in alkaline environments. In industrial production, many equipment, pipelines, furnaces, etc. are exposed to alkaline substances, such as sodium hydroxide, potassium hydroxide and other strong alkalis.

Applications:It is widely used in industrial furnaces with alkali corrosion in industries such as steel, nonferrous metals, glass, machinery, and petrochemicals.

| Items | RS-13NL | RS-14N | |

| Chemical Composition % | Al2O3 | 48 | 45 |

| Bulk Density g/cm 3 | 110℃x24h | 2.2-2.4 | 2.2-24 |

| MOR MPa | 110℃x24h | 7 | 8 |

| 1110℃x3h | 7 | 8 | |

| Cold Crushing Strength MPa | 110℃x24h | 70 | 80 |

| 1110℃x3h | 70 | 80 | |

| Linear Dimensional Change% | 1110℃x3h | ±0.4 | ±0.4 |

| Maximum Service Temperature ℃ | 1300 | 1400 | |

High Alumina Castable

Main Features:High-alumina castables combine high-temperature stability, mechanical strength and thermal shock resistance through high aluminum content, dense structure and scientific proportioning, making them the preferred material for linings of high-temperature industrial equipment.

Applications:It is widely used in high temperature kiln linings in the steel, non-ferrous metals, chemical, ceramics and other industries, such as blast furnaces, hot blast furnaces, ceramic kilns, etc.

| Item | Specification | ||||

| NM-1 | NM-2 | NM-3 | NM-4 | ||

| Al2O3 % | ≥70 | ≥75 | ≥80 | ≥85 | |

| Bulk Density, g/cm3 110℃×24h | ≥2.6 | ≥2.75 | ≥2.8 | ≥2.9 | |

| CCS,MPa | 110℃×24h | ≥60 | ≥65 | ≥70 | ≥75 |

| 1400℃×3h | ≥90 | ≥95 | ≥105 | ≥110 | |

| CMOR, MPa | 110℃×24h | ≥8.5 | ≥9 | ≥10 | ≥11 |

| 1400℃×3h | ≥13 | ≥14 | ≥15 | ≥16 | |

| Cold Wear Loss, cm3 | <9.6 | <8.5 | <7.3 | <6 | |

| 0.2MPa RUL,℃ | >1450 | >1490 | >1530 | >1560 | |

| TSR, Cycle 900℃ Water | >20 | >20 | >20 | >20 | |

| Max Working Temperature, ℃ | 1550 | 1550 | 1600 | 1600 | |

| PLC, % | <-0.3 | <-0.3 | <-0.2 | <-0.2 | |

Al2O3-SiC-C Castable

Main Features:The castable used for the lining of the blast furnace tapping channel is a kind of high-alumina refractory castable containing silicon carbide and carbon. It has the characteristics of large iron flow, long service life, low refractory material consumption and convenient construction.

Applications:It is widely used in the working layer of blast furnace main groove, iron groove, slag groove and swing flow channel, as well as spray coating for hot repair.

| Item | Specification | ||||

| Slag Line of Main Iron Runner | Iron Line of Main Iron Runner | Branch Iron Runner | Slag Runner | ||

| Al2O3 % | 56~60 | 75~70 | 70~72 | 65~68 | |

| SiC % | 15~30 | 12~15 | 12~15 | 15~18 | |

| Bulk Density, g/cm3 | 110℃×24h | 2.9~3.0 | 2.9~3.0 | 2.75~2.8 | 2.65~2.7 |

| 1450℃×3h | 2.85~2.9 | 2.85~2.95 | 2.7~2.75 | 2.6~2.65 | |

| CCS, MPa | 110℃×24h | 35~40 | 35~40 | 30~35 | 25~30 |

| 1450℃×3h | 50~60 | 45~65 | 35~40 | 35~40 | |

| CMOR, MPa | 110℃×24h | 4~8 | 4.5~3.5 | 5~6 | 6~7 |

| 1450℃×3h | 6~7 | 5.5~7.0 | 8~10 | 7~8 | |

| HMOR, MPa

1450℃×0.5h |

>1.5 | >2.5 | >3 | >1.5 | |

| PLC, %

1450℃×3h |

+(0.1~0.2) | +(0.1~0.3) | +(0.1~0.2) | +(0.1~0.2) | |

Corundum Castable

Main Features:Corundum castable is a refractory castable made of clay and high-alumina raw materials as aggregate and powder, and added with binders. It has high fire resistance and thermal shock stability, resistance to sulfur and salt corrosion, and is acid and alkaline resistant, high in strength, and has no cracks or peeling after firing.

Applications:It is widely used in the working layer of blast furnace main groove, iron groove, slag groove and swing flow channel, as well as spray coating for hot repair.

| Item | Data | ||||

| Chemical Composition | AL2O3≥ | 70 | 75 | 80 | 85 |

| SiO2≤ | 26 | 21 | 16 | 11 | |

| CaO≥ | 2.5 | 1.5 | 1.2 | 1 | |

| Flexural Strength(Mpa) | 110℃×24h≥ | 8 | 11 | 12 | 13 |

| 815℃×3h≥ | 9 | 12 | 13 | 14 | |

| 1100℃×3h≥ | 10 | 13 | 14 | 15 | |

| Compressive Strength(Mpa) | 110℃×24h≥ | 70 | 80 | 85 | 90 |

| 815℃×3h≥ | 80 | 85 | 90 | 95 | |

| 1100℃×3h≥ | 85 | 90 | 95 | 110 | |

| Bulk Density(g/cm3) | 2.75 | 2.85 | 2.9 | 2.95 | |

| General Wear And Tear(CC≤) | 7 | 6 | 6 | 5 | |

| Thermal Shock Stability (900℃ Water Cooling), Times≥ | 25 | 20 | 25 | 20 | |

Steel Ladle Castable

Main Features:Ladle castable is a refractory material specially used for ladle lining. It is mainly made of corundum, alumina-magnesium spinel, fused magnesia and other raw materials. It has excellent refractory properties, slag erosion resistance and thermal shock resistance.

Applications:It is widely used in ordinary steel ladles, refined steel ladles, electric furnace ladles, etc. It is also used in metallurgical industrial furnaces, as well as furnaces and thermal equipment in the petroleum, chemical, building materials, electric power, machinery and other industries.

| Item | Alumina magnesia castable | Alumina magnesia castable | High alumina castable |

| Application | Working lining | Working lining | Permanent lining |

| Al2O3 %≥ | 60 | 70 | 60 |

| MgO % ≥ | 12 | 10 | / |

| C % | / | / | / |

| Refractoriness ℃≥ | / | / | 1790 |

| RUL ℃ ≥ | 1200 | 1350 | / |

| LCR % (1400℃,2h) | 0~2 | 0~2 | 0~0.3 |

| Apparent porosity % ≤ | 23 | 25 | 18 |

| CCS MPa ≥ | 30 | 30 | 30 |

| Max. working temperature ℃ | 1700 | 1700 | 1650 |

Low Cement Castable

Main Features:Low Cement Castable (LCC) is a high-performance refractory material made by optimizing the cement content (usually CaO content is between 1.0%-2.5%) and using ultra-fine powder technology. Compared with traditional general castables, it has higher strength, lower porosity and better corrosion resistance.

Applications:It is widely used in refractory linings of high-temperature furnaces, kilns and other equipment in metallurgy, petrochemical, electric power, building materials and other industries.

| Item | Specification | |||

| Clay | High Alumina | Corundum | ||

| Al2O3 % | ≥45 | ≥75 | ≥98 | |

| CaO % | <1.8 | <1.5 | <1.0 | |

| Bulk Density, g/cm3 | 110℃×24h | ≥2.3 | ≥2.6 | ≥3.1 |

| 1350℃×3h | ≥2.26 | ≥2.61 | / | |

| 1550℃×3h | / | / | ≥3.00 | |

| CCS, MPa | 110℃×24h | ≥70 | ≥75 | ≥85 |

| 1350℃×3h | ≥85 | ≥90 | / | |

| 1550℃×3h | / | / | ≥100 | |

| CMOR, MPa | 110℃×24h | ≥6 | ≥8 | ≥9 |

| 1350℃×3h | ≥8 | ≥9 | / | |

| 1550℃×3h | / | / | ≥11 | |

| PLC, % | 1000℃×3h | -0.3 | -0.2 | -0.2 |

| 1350℃×3h | ±0.3 | ±0.5 | / | |

| 1550℃×3h | / | / | ±0.5 | |

| Max Working Temperature, ℃ | 1450 | 1600 | 1800 | |

➤Rongsheng Refractory Castables Application

We Rongsheng Company are able to supply all kinds of refractory castables (also including other refractory material) that widely are used in Steel Industry, Petrochemical Industry, Metallurgy Industry, Noferrous Industry and Building Industry and suitable for different Furnace/Kiln, such as Glass Kiln, Tundish Furnace, Steel Casting Lable, Cement Kiln, Electric Arc Furnace ,Torpedo Ladle and other various Furnace. If you have interests for our refractory castables and kindly tell which furnace you are using, then our professional engineer will design the drawing with recommended suitable castables in every part of your furnace/ kiln.

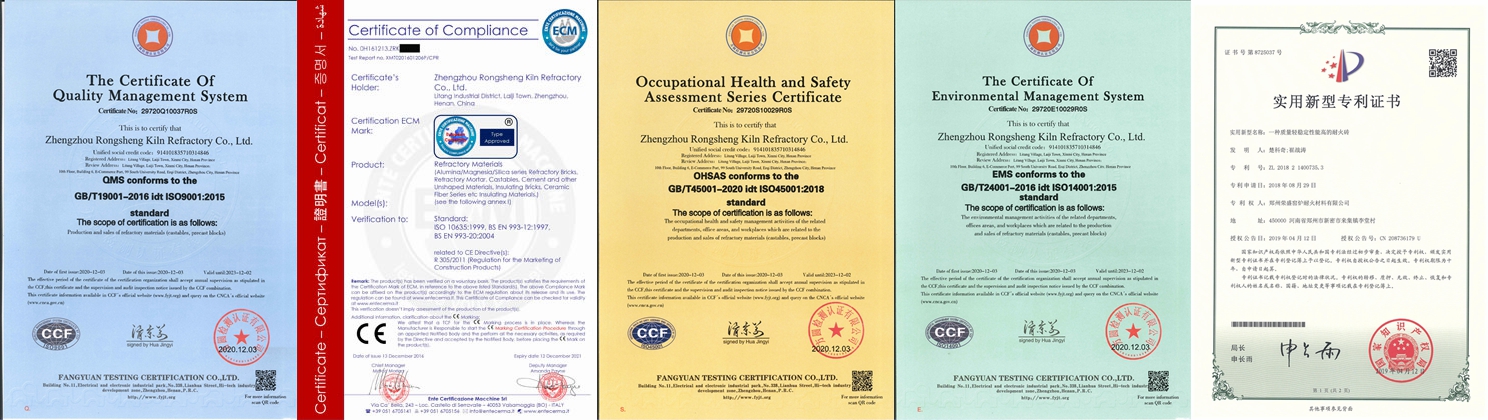

➤Certifications Of Rongsheng Company

➤Clients Visiting our factory

➤Why choose Rongsheng as supplier