Product Introduction

AZS brick, the full name is fused zirconium corundum brick (abbreviated as AZS in English), is a high-performance refractory material with alumina (Al₂O₃), zirconium oxide (ZrO₂) and silicon dioxide (SiO₂) as the main components.

The naming of AZS brick is based on the content of Al₂O₃, ZrO₂, and SiO₂, which are represented by A, Z, and S respectively. For example, AZS-33# means ZrO₂ about 33%, AZS#36 means ZrO₂ about 36%, and AZS#41 means ZrO₂ about 41%.

Technical Data Of Rongsheng AZS Brick

| Brand | Rongsheng Fused Cast AZS Brick | |||

| Model | AZS#33 | AZS#36 | AZS#41 | |

| Chemical Composition % | Al2O3 | 50 | 49 | 45 |

| ZrO2 | 32~36 | 35~40 | 40~44 | |

| SiO2 | ≤16 | ≤14 | ≤13 | |

| Na2O+K2O | ≤1.30 | ≤1.35 | ≤1.30 | |

| Volume density g/cm3 | ≥3.75 | ≥3.8 | ≥3.95 | |

| Apparent Porosity % | ≤1.5 | ≤1.0 | ≤1.0 | |

| Cold Crushing Strength Mpa | ≥200 | ≥200 | ≥200 | |

| Exudation Temperature of Glass Phase | ≥1400 | ≥1400 | ≥1410 | |

| Bubble Separation Ratio(1300℃×10h) | ≤2.0 | ≤1.5 | ≤1.0 | |

| Anti-corrosion rate of glass liquid 1500℃×36h (mm/24h)% | ≤1.6 | ≤1.5 | ≤1.3 | |

| Bulk density(g/cm3) | Ordinary casting PT(RN RC N) | ≥3.55 | ≥3.55 | ≥3.70 |

| No shrinking casting ZWS(RR EVF EC ENC) | ≥3.65 | ≥3.75 | ≥3.85 | |

| Tilt casting QX(RO) | ≥3.65 | ≥3.75 | ≥3.90 | |

| No shrinkage castingWS( RT VF EPIC FVP DCL) | ≥3.75 | ≥3.80 | ≥3.95 | |

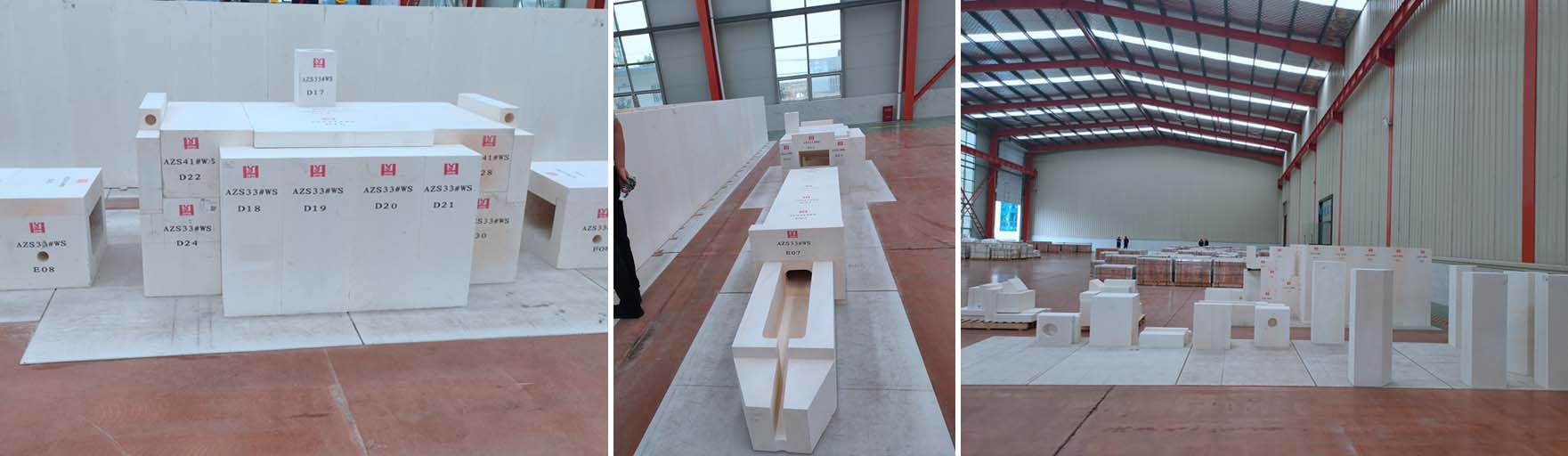

Application

AZS#33 Brick is widely used for glass furnace for superstructure, working pool side wall, paving blocks, feeder channels, tank bottom, C-shaped block and doghouse crown,etc. AZS#36 Brick is mainly used for sidewall, doghouses, throat, bottom budding, Dam blocks, electric block corners. AZS#41 Brick is mainly used for sidewalls, doghouses, bottom budding, Dam blocks, electric block corners.