I. Core Conclusions

Acid-resistant ceramic tiles focus on corrosion protection in ambient to medium-low temperature environments (such as chemical tanks and acid trenches), while acid-resistant refractory bricks specialize in structural stability in high-temperature environments (such as kilns and metallurgical equipment). The two differ significantly in composition, performance, and construction, requiring a suitable match based on actual operating conditions.

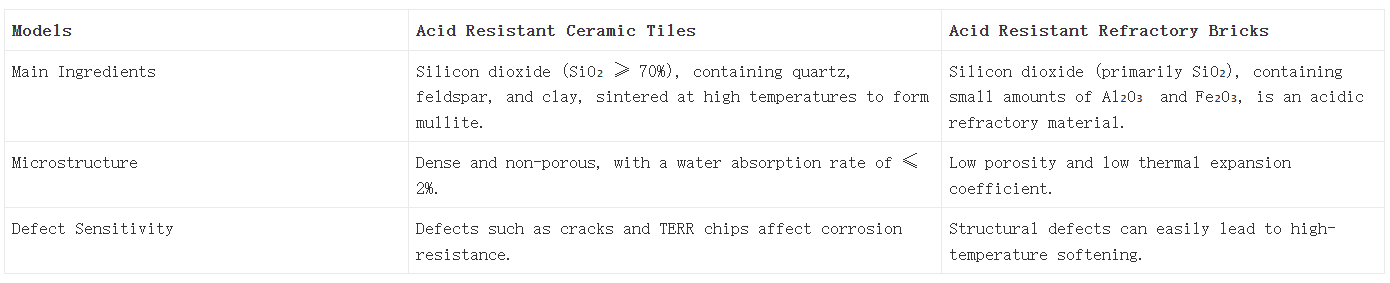

II. Composition and Structure Comparison

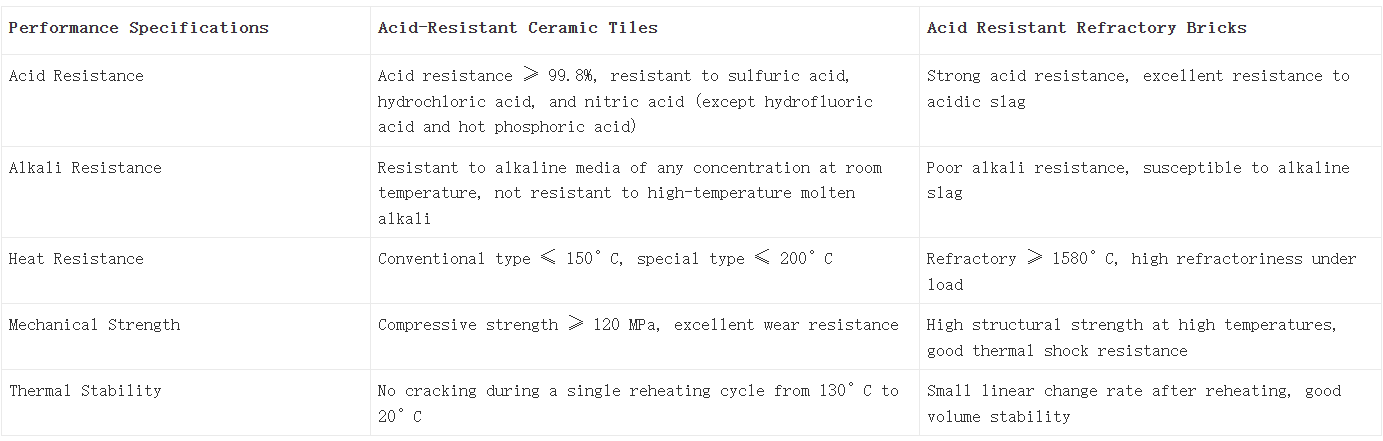

Ⅲ. Performance Parameter Comparison

IV. Differences in Application Scenarios

1. Acid-Resistant Ceramic Tiles: Prioritize Corrosion Resistance

Industrial Applications:

Chemical Storage Tanks, Acid Ditches, and Acid Well Linings (Contact with Sulfuric Acid, Hydrochloric Acid, etc.)

Electroplating Workshops, Wastewater Treatment Floors for Corrosion Protection

Acidic Media Handling Areas in Food/Pharmaceutical Plants

2. Acid-Resistant Refractory Bricks: Prioritize High-Temperature Stability

Metallurgical Applications:

Coke Ovens, Glass Melting Furnaces, and Acidic Steelmaking Furnace Linings

Chimneys and High-Temperature Area Masonry

Special Applications:

Equipment Requiring Both Acid and High-Temperature Resistance (e.g., High-Temperature Pickling Furnaces)

VI. Purchasing Recommendations

Highly Corrosive Environments with Normal Temperatures (e.g., Chemical Tanks) → Choose Acid-Resistant Ceramic Tiles

High Temperature Environments with Acidic Media (e.g., Glass Melting Furnaces) → Choose Acid-Resistant Refractory Bricks

Complex Applications (e.g., Chimney Linings) → Choose Acid-Resistant and Heat-Resistant Bricks (Combining Corrosion Resistance and Refractory Properties)