Brief Introduction

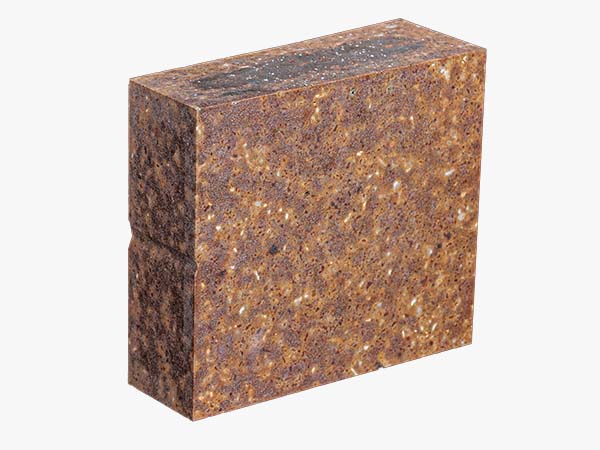

Silicon-mullite brick is a refractory material mainly composed of silicate and mullite (a mineral containing aluminum and silicon). This material has high refractoriness, thermal shock resistance and erosion resistance, and is widely used in steel smelting, cement production, glass manufacturing and other industries.

Index Of Rongsheng Silicon Mullite Brick

| Brand | RSAZM-1550 | RSAZM-1650 | RSAZM-1680 |

| Al2O3,% ≥ | 65 | 63 | 60 |

| °C Refractoriness ≥ | 1790 | 1790 | 1790 |

| Bulk Density, g/cm3 | 2.50 | 2.55 | 2.60 |

| Apparent Porosity % | 20 | 20 | 21 |

| CCS,MPa ≥ | 80 | 90 | 95 |

| Mpa, MOR ≥ | 8 | 12 | 15 |

| 0.2Mpa Softening Temperature Under Load °C, RUL ≥ | 1550 | 1650 | 1680 |

| TSR, Water-Cycle | 10 | 12 | 15 |

| CC, CWT | — | 8.2 | 8.5 |