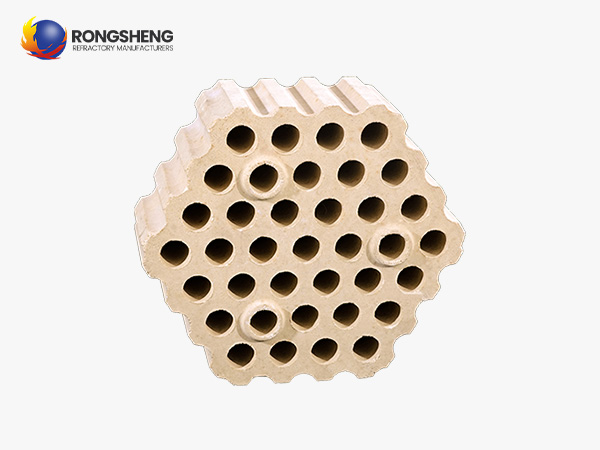

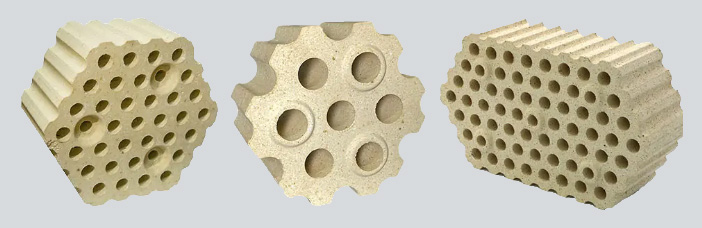

Product Introduction

Checker brick is a heat transfer medium used in hot blast stoves, glass kilns, etc. And high-alumina checker brick is a heat-carrying and heat-storing body with strong heat exchange capacity, large heat storage area, smooth ventilation, and small resistance. It has the advantages of good volume stability, excellent high-temperature creep performance, high density and low porosity.

Choose the type what you need, or provide the size you need.

Technical Data

| RongSheng Checker Brick Physical and Chemical Index: | ||||||

| Item | Properties | |||||

| RS-80 | RS-75 | RS-65 | RS-55 | RS-48 | ||

| Al2O3 (%) | 80 | ≥75 | ≥65 | ≥55 | ≥48 | |

| Refractoriness (°C ) | ≥1790 | ≥1790 | ≥1790 | ≥1770 | ≥1750 | |

| Bulk density (g/cm3) | 2.65 | 2.5 | 2.45 | 2.4 | 2.3 | |

| Softening temperature under load (°C ) | 1530 | ≥1520 | ≥1500 | ≥1470 | ≥1420 | |

| ReheatingLinear Change Rate (%) | 1500°CX2H | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| 1450°CX2H | -0.4 | -0.4 | -0.4 | -0.4 | -0.4 | |

| Apparent porosity (%) | 22 | ≤23 | ≤23 | ≤22 | ≤22 | |

| Cold crushing strength (Mpa) | 55 | ≥50 | ≥45 | ≥40 | ≥35 | |

| Application | steel furnace, glass furnace, sodium silicate furnace, ceramic shuttle kiln, cement rotary kiln, blast furnace, electric furnace, blast furnace and reverberatory furnace. | |||||

Application

1. Steel furnaces

2. Iron making furnaces

3. Glass kiln

4. Ceramic tunnel kiln

5. Cement kiln